In the previous blog, I discussed the building sewer, which is essentially the piping that carries waste from a building to a waste treatment system. Picking up where the building sewer terminates, we will discuss in more detail the next component: the septic tank. This information is based on a typical new construction and represents general code requirements and site, soil and climate conditions which can greatly vary.

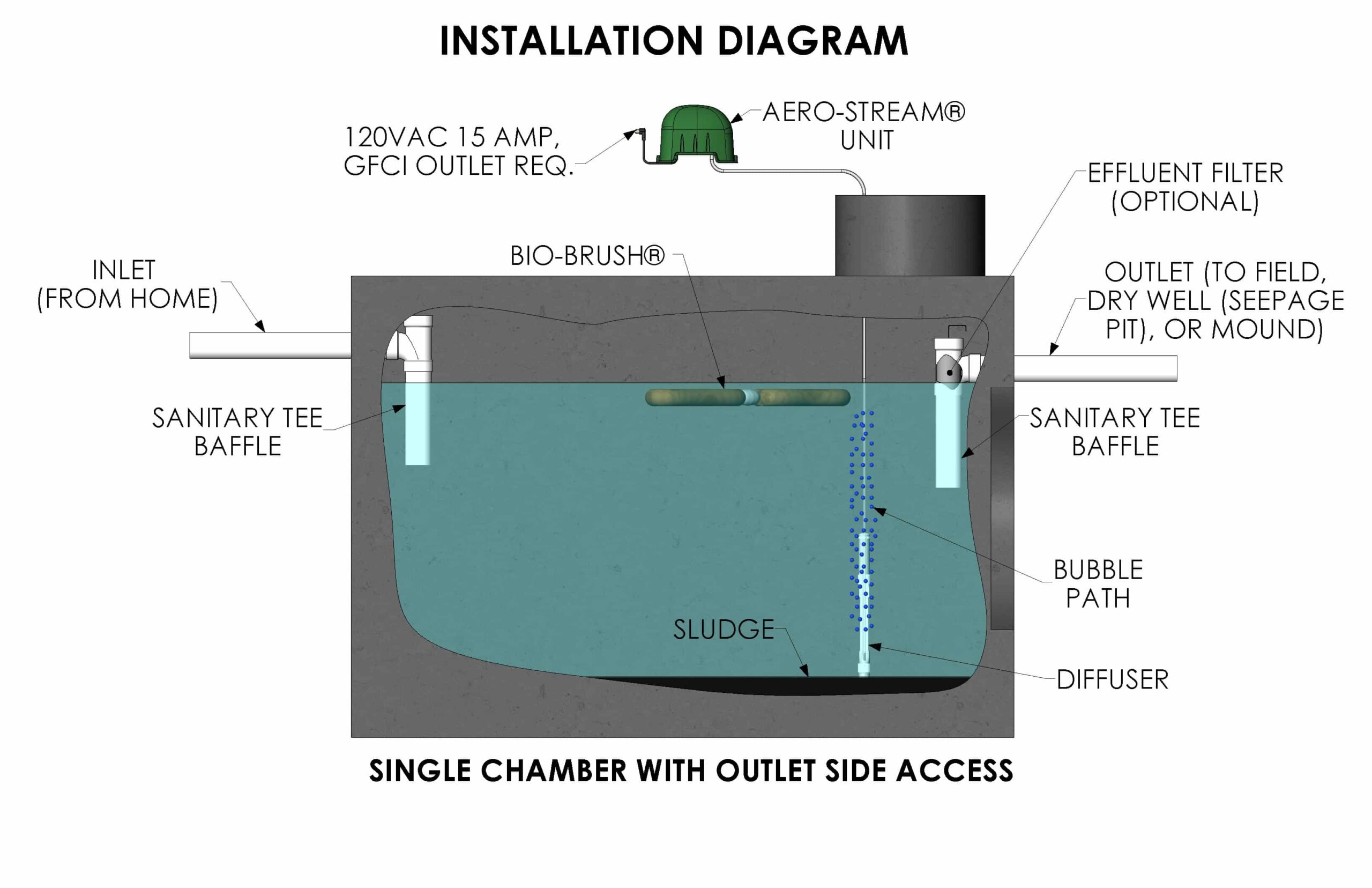

The basic purpose of the septic tank is to retain waste water to allow naturally occurring bacteria to begin processing the waste and to allow separation to occur within the tank. The tank retains a sludge layer which sinks and a scum layer which floats and keeps these from exiting the tank.

Septic tanks have been made of many materials in the past, from barrels to open pits made of brick, wood, stone and metal. The majority of septic tanks today are constructed of concrete, plastics, and fiberglass; in some parts of the country local materials such as redwood are utilized. The choice of septic tank material is often dependent on what is locally available and access to the building site. Sites that do not have access to allow the heavy equipment necessary to place concrete tanks can utilize the light weight plastic tanks that can be hand carried to the site.

The location of the septic tank is governed by locations of wells and waterways. The reason these are considered when placing a tank within a site is to reduce the chance of contaminating drinking supplies with sewage. Not surprisingly, many municipalities have regulations and set backs that must be maintained to reduce human and environmental health hazards.

The connection to the septic tank from the building sewer is also often required to be a mechanical joint or a solvent cement joint. In areas where regional flooding and/or high ground water occurs, the connections to and from the septic tank must be made water tight. Many states in the US also require specific care and attention be paid to minimizing any settling from occurring by both tamping the soil beneath the tank and by using materials that will evenly support the tank such as pea gravel or any other level, granular material. Fine grained soils such as clay and silts is not preferable as a base for the tank due to the freeze and thaw process causing more shifting in these soil types than more granular soils such as sand and gravel. It is also important to install tanks level, so that maximum retention time and separation can occur.

Some municipalities require manhole access to the tank for routine maintenance and pumping. While not required everywhere a large opening, as opposed to a small diameter pump out location, allows the tank to be visually inspected after pumping allowing the integrity of the tank to be observed. Filters added to the waste water outlet of the tank are becoming required in more locations and need routine maintenance and hence easy access. If repairs are needed within the tank, it requires special breathing apparatus as high levels of toxic gases and lack of oxygen within the septic tank are harmful. It is also important to make sure that access to the septic tank is limited using a lockable cover and/or adding a net within the tank will keep curious children and animals safe.

The majority of tanks rely on the houses vent stack to vent out the gasses that are produced in the septic tank as waste is being processed by bacteria, but some septic tanks and plumbing systems rely on vents on the septic tank, although this does increase the possibility of odors being recognized. In these cases, adding aeration (utilizing more aggressive bacteria) will eliminate the odor.

Septic tanks also vary greatly in size, commonly measured in gallons, and the number of compartments within the tank. Please look in a future blog for details about the theory behind tank size and use as well as the benefits of compartments within a tank.