There seems to be a mystery about hydrogen sulfide and septic systems. In some areas of the country the damage related to hydrogen sulfide is severe, and in other areas it is a non-issue. Let us begin by first understanding the issues surrounding hydrogen sulfide and septic tanks:

- Hydrogen sulfide (H2S) is a byproduct of the anaerobic digestion that occurs in a common septic tank.

- The naturally occurring thiobacillus bacteria excrete the gas during the digestion of organic material in the septic tank.

- The gas accumulates in the headspace above the water line in the tank, distribution box and lateral lines.

- When the hydrogen sulfide gas mixes with water vapor and low levels of oxygen they form sulfuric acid (H2SO4).

The sulfuric acid attacks the concrete from which the tank, distribution box and septic tank riser is made. Depending on the conditions, severe deterioration of the concrete can occur in a few years. Plastic septic tank risers are not affected by the hydrogen sulfide gas and acid.

Sulfuric acid causing spalling concrete and exposing steel mesh

Signs of deterioration are spalling of the concrete surface, white formations of ettringite (calcium sulfoaluminate) on the surface of the concrete just above the water line and exposure of rebar and reinforcing steel that was once encapsulated in the concrete.

The sulfuric acid will also corrode steel components within the septic tank, such as exposed reinforcing steel, steel baffles and steel fasteners. It is our experience that water supplies with high iron and sulfur content are most prone to experience production of hydrogen sulfide.

If your septic tank has visible signs of deterioration, there is a good chance that your concrete d-box is also suffering from deterioration. On the other hand, if your tank is not showing signs of deterioration, we cannot conclude that the d-box is not being affected. The reason for this is that the concrete used for the d-box may not be of the same quality as the septic tank or the environmental conditions within the d-box could be ideal for the production of sulfuric acid.

Effects of corrosion from sulfuric acid on concrete septic tank riser

There is no practical way to reverse the damage done by the sulfuric acid. If the structural integrity of the tank is questionable, it should be inspected by a competent professional. If the tank is structurally sound your in luck!

Fortunately, further deterioration can be avoided by eliminating the root cause of the problem, the thiobacillus bacteria. The thiobacillus bacteria survive in an anaerobic environment (lacking oxygen). When exposed to an aerobic environment, the bacteria cannot survive, thus halting the production of hydrogen sulfide.

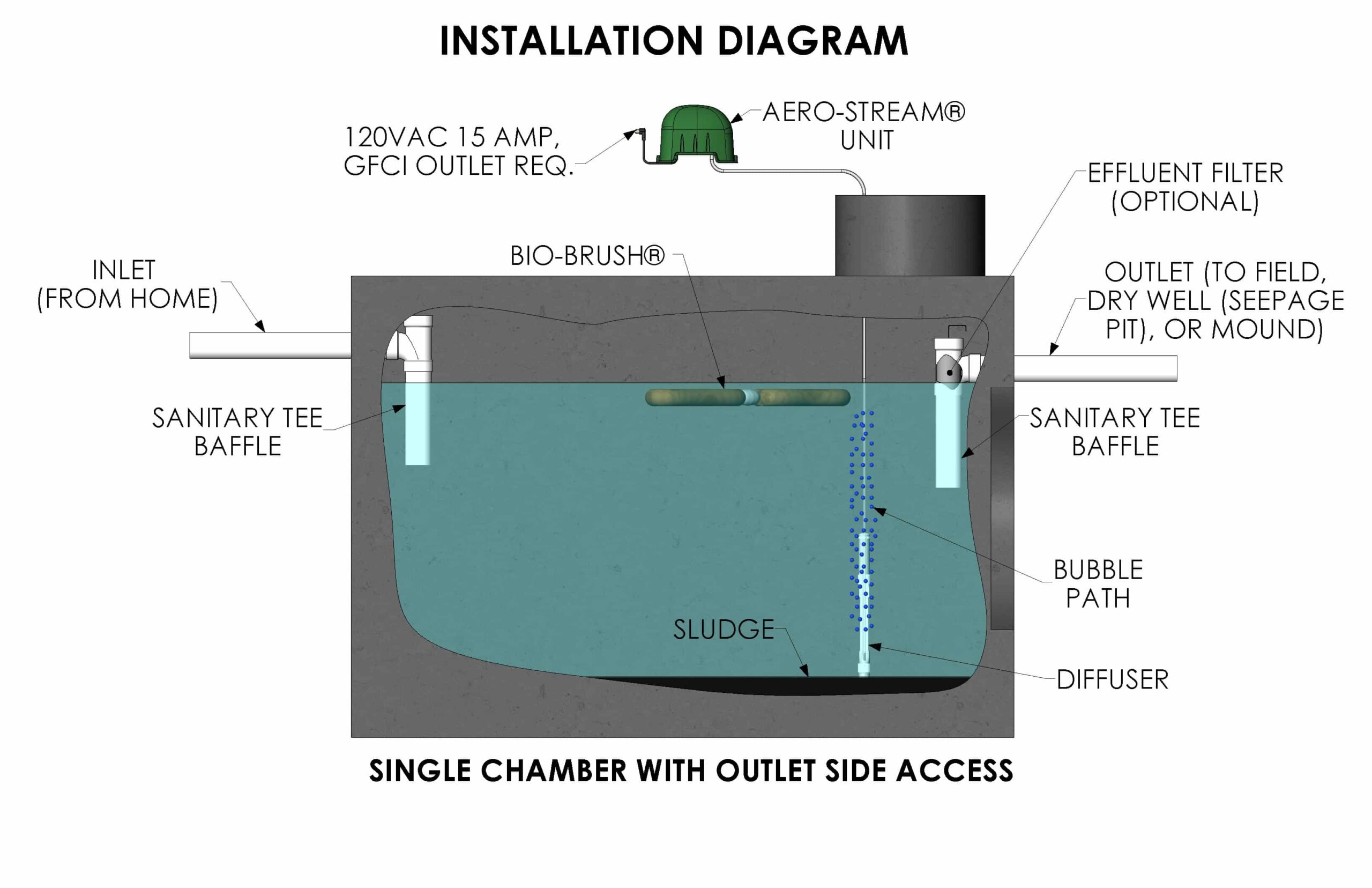

To successfully convert the environment to aerobic, the water in the tank AND the head space above the water must be oxygen rich. By installing the proven Aero-Stream Septic Restoration process, the water and the head space will be oxygenated. All deterioration will be promptly halted. In addition to saving your tank from complete failure, you will gain the benefit of extending the life of your drainfield by preventing the growth of the bio mat. Your tank should be inspected for deterioration promptly, especially if you have high iron and high sulfur (rotten egg) odor.