SEPTIC TANK RISER ADAPTER FLANGE/INGRESS BARRIER

BACKGROUND OF THE INVENTION

The invention relates generally to the septic tank access ports installed in septic systems.

Discussion of the Related Art

In order to perform maintenance on septic tanks access ports, which are commonly referred to as tank risers or risers, are installed on the openings to the chamber(s) of the septic tank. The openings on the chambers can vary in size and shape, such as round, square, or rectangular. Riser construction can vary in height and diameter, and many extend to the ground surface. Some riser openings are large enough in diameter to allow human ingress.

Riser construction may be comprised of an adapter ring, riser pipe, ingress barrier, and a lid. Because of the wide variety of tank opening sizes and shapes, it is desirable to provide a large adapter flange that will accommodate the range of tank opening geometry. Many adapter rings are round and only slightly larger than the riser pipe diameter. The compact and round adapter flanges limit the applications in the field. A large adapter flange is more expensive to produce and ship to customers as compared to a compact adapter flange.

In the instances where the riser pipe diameter is large enough for human ingress, ingress barrier devices, usually comprised of screens, lids, or nets, are often installed at the top of the riser to prevent accidental ingress into the septic tank. These ingress devices are usually fastened to the 25 riser pipe or an adapter device and may contain openings that allow septic cleaning and pumping equipment access to the inside of the septic tank.

Although there is a number of prior art devices that perform the function of preventing accidental ingress into the septic tank, all of the devices are designed to be installed at the top of the riser 30 pipe utilizing visible fasteners. This location and attachment method provides an opportunity for tampering and unauthorized personnel to access and remove the ingress device fasteners and ingress device. Ingress devices using visible fasteners are susceptible to the possibility that the fasteners may not have been installed at origination or may not be reinstalled after being removed by service personnel. This could result in accidental ingress caused by easily defeating 35 the ingress device, exposing a potentially dangerous situation.

An ingress device that is located lower in the riser pipe and features hidden fasteners but still allows access to the inside of the septic tank for maintenance is desired.

SUMMARY OF THE INVENTION

A relatively large square adapter flange/ingress barrier device containing integral accidental ingress features has been designed. This device is intended to be installed at the access opening of the septic tank and interface with the riser pipe providing a tamper-proof barrier for the prevention of accidental ingress. The ingress barrier may contain openings of any geometric 10 shape including, but not limited to, triangles, squares, or circles. Physically defeating the ingress barrier is made more difficult by locating it lower in the riser pipe and attaching it with hidden fasteners thereby reducing the likelihood that the ingress barrier could be defeated.

To address the excessive cost to produce and ship, a relatively large adapter flange, the flange has been designed as four (4) identical sections that snap together in the field at assembly. The multi-piece flange design makes it possible to reduce the shipping container size and cost.

The integrated ingress barrier is designed to allow inspection and cleaning activities on the septic tank to be performed without having to be removed. Clearance for pumping and inspection 20 equipment to pass through into the septic tank has been designed into the ingress barrier openings.

BRIEF DESCRIPTION OF THE DRAWINGS

The invention is illustrated in the accompanying drawings and sketches. Key elements of the invention are identified by reference numbers that are subsequently used in describing the invention and claims.

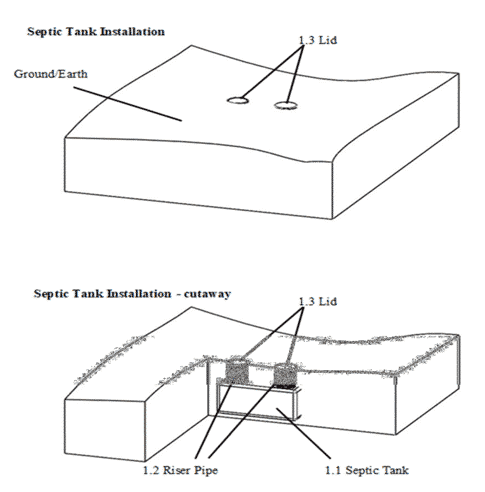

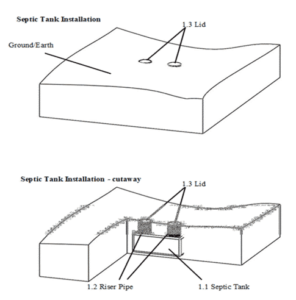

1. Figure 1 Overall Septic System

1.1 Septic tank-reference

1.2 Riser Pipe-reference

1.3 Lid-reference

A generic illustration of a common sub-surface septic system including the systems relation to earth grade.

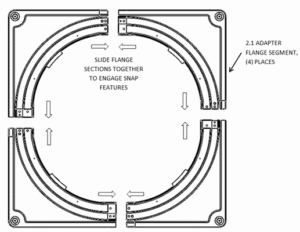

2. Figure 2 Assembly Method of Segmented Adapter Flange

2.1 Adapter Flange

A generic illustration of the adapter flange assembly. The adapter flange segments (2.1) slide into their adjacent components and lock into place with a snap retaining feature.

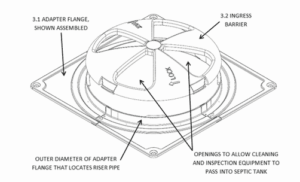

3. Figure 3 Key Design Elements of the Adapter Flange/Ingress Barrier

3.1 Adapter Flange

3.2 Ingress Barrier

A generic illustration of the adapter flange (3.1). The flange provides alignment features to pilot 10 the location of the riser pipe (not shown). The ingress barrier has an opening to allow inspection and cleaning equipment to pass into the septic tank.

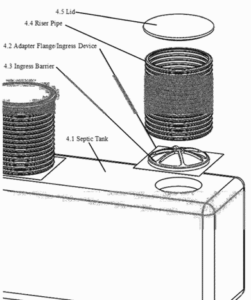

4. Figure 4 Figure 4 Exploded View of Septic System

4.1 Septic Tank

4.2 Adapter Flange

4.3 Ingress Barrier

4.4 Riser Pipe

4.5 Lid

A generic illustration of a septic tank is shown in Figure 4 Exploded View of Septic System.

The adapter flange (4.2) is fixed to the septic tank (4.1) by means of adhesive, caulk, concrete or threaded fasteners, or any combination of the aforementioned. The riser pipe (4.4) is piloted over and attached to the outer diameter of the adapter flange (4.2). The pipe is attached to the flange with threaded fasteners. The ingress barrier (4.3) connects to the adapter flange (4.2) using molded-in-thread features. The lid (4.5) is seated on the riser pipe (4.4) and is secured using threaded fasteners.

HOW TO MAKE THE INVENTION

The adapter flange and ingress device may be fabricated from polymer material, sheet metal, steel reinforced concrete or any other materials as required to fit the size of the access port on the septic tank.

The ingress barrier can be manufactured as an integral part of the adapter flange with a secondary operation to trim the ingress barrier from the flange to create two-(2) parts.

Alternatively, the adapter flange and ingress barrier can be molded as a single piece or as multiple segments that are assembled together. The multiple segments of the flange are assembled together using any method including snap features, mechanical fasteners, adhesives, welding or any combination thereof.

The ingress barrier can then be installed into the riser assembly and fastened into place using any method including hidden mechanical fasteners, molded tabs, threads, snap features, etc. for removal by authorized personnel.

Figure 1 Overall Septic System

Figure 2 Assembly Method of Segmented Adapter Flange

Figure 3 Key Design Elements of the Adapter Flange/Ingress Barrier

Figure 4 Exploded View of Septic System

Let the experts at Aero-Stream® diagnose your problem and guide you through the solution saving you money and stress. Experience First-Class Customer Service and Septic System Knowledge. Eliminate the Stress! Call Anytime (877) 254-7093