Advanced Wastewater Treatment Systems

Recently I was chatting with a septic system design engineer about advanced wastewater treatment systems. This gentleman is an accomplished engineer, is a licensed P.E. in the state of Colorado, and has spent many years designing systems in accordance with the Colorado code. My impression was that he knows the Colorado code very well and considers all options to design the best treatment system for his clients that are cost-effective and efficient.

I would consider him an expert in the field of wastewater treatment system design. I on the other hand have spent 22 years of my engineering career troubleshooting and restoring failed systems across North America. I suspect all but a handful of the tens of thousands of septic systems we have restored were designed and installed according to state and local codes. These systems have failed in as little as a few years and others have functioned for 40 years.

The average septic system useful life expectancy is 15 – 20 years. We have restored every conceivable system type from conventional stone and pipe leach fields, sand mounds, sand filters, chambered systems, and drip systems, to complex aerobic treatment units and everything in between. You’re about to learn why aerobic treatment is superior to anaerobic treatment.

The purpose of my call to him was to introduce our new ANSI/NSF 40 Aerobic Treatment Unit product line. The engineer went on to explain the code details and design options per REGULATION NO. 43 – ON-SITE WASTEWATER TREATMENT SYSTEM REGULATION 5 CCR 1002-43 he had for various soil types. He primarily designs systems installed on the Front Range (Denver, Fort Collins to the North and Colorado Springs to the South). He also designs systems in the foothills to the West of this area. The Front Range soils have high clay content, and the foothills have high rock content.

Colorado Wastewater Treatment Systems

In Colorado, there are 5 main treatment levels. The treatment levels are TL1, TL2, TL2N TL3, and TL3N. TL1 is a standard septic system. It is a passive system that has a 2-compartment septic tank and a leach field. The effluent can be distributed by gravity to the absorption component. About 40% of the conventional systems use chambers to distribute the effluent and the balance use conventional stone and pipe. A chamber is like a half-round of a pipe. The sections are roughly 3’ – 5’ in length and they are laid in a trench end to end to achieve the required surface area to apply the effluent to the soil.

In Colorado, there are 5 main treatment levels. The treatment levels are TL1, TL2, TL2N TL3, and TL3N. TL1 is a standard septic system. It is a passive system that has a 2-compartment septic tank and a leach field. The effluent can be distributed by gravity to the absorption component. About 40% of the conventional systems use chambers to distribute the effluent and the balance use conventional stone and pipe. A chamber is like a half-round of a pipe. The sections are roughly 3’ – 5’ in length and they are laid in a trench end to end to achieve the required surface area to apply the effluent to the soil.

In some designs, tire chips are substituted for stone. The TL1 treatment level assumes the treated effluent will have a BOD5 of 180 mg/l and the TSS less than 80 mg/l. These values are assumed to be the limits based on collected field data. We should note that these limits are not absolute. A conventional treatment system will only reduce the strength of the influent by about 40%. Therefore, if the influent strength is greater than 450 mg/l the effluent strength will be greater than 180 mg/l. The Colorado code considers influent strength greater than 300 mg/l as “High Strength” wastewater.

Unfortunately, the state does not monitor effluent strengths for residential systems. They assume all households are the same and the influent strength is typically < 300 mg/l BOD5. TL2 can either be a passive sand filter or a mechanical aerobic treatment unit. The effluent must be pressure dosed to the absorption component. The sand filter designs utilize a layer of sand in the bottom of a field or trench. The depth of the layer of sand can be one foot thick to three feet thick depending on the desired hydraulic loading rate and soil type.

The code allows for a 5% – 60% increase in loading rate when the trench is filled with two feet of sand depending on soil types. TL2 treatment systems are classified to produce effluent with a CBOD5 less than 25 mg/l and TSS less than 30 mg/l. Ironically, when specifying a sand bed TL2 system, the effluent leaving the septic tank is of the same strength as a TL1 system. These designs rely on the layer of sand to achieve the improved treatment level required by the TL2 designation.

And again, if the influent is greater than 450 mg/l the effluent will be stronger than 180 mg/l, thus the BOD5 of the water passing through the sand could be greater than 25 mg/l. A TL2N system has the same effluent strength requirements as the TL2 with the addition of a 50% reduction in Total Nitrogen in mg/l. TL3 is similar to the TLN2 except the maximum effluent strength is 10 mg/l CBOD5 and 10 mg/l TSS. This level of treatment can typically only be achieved with a mechanical aerobic treatment unit. TL3N treatment level is like the TL3 with the addition of a 50% reduction in Total Nitrogen in mg/l.

In addition to treatment levels, the design engineer has some other options when it comes to the soil treatment area and distribution media. The code allows for the reduction of the soil treatment square footage when a trench is used as compared to a bed. The reason for this is that a trench allows for absorption on the sidewalls of the trench. If the effluent is dosed via a siphon or pump the soil treatment area can be reduced by 20% for a trench vs. a bed. A siphon or pump implies that the effluent is distributed by low-pressure means and is intended to “flood” the soil treatment area. If pressure dosing is used the soil treatment area can be reduced in size by 20% for a trench vs a bed. Pressure dosing is achieved by pumping the effluent at a higher pressure through a smaller diameter piping system that will have holes or nozzles to spray the effluent into the soil.

Three Categories Of Distributed Media

There are three categories of distribution media. They are Category 1 – rock or tire chips, Category 2 – other manufactured media, and Category 3 – chambers or enhanced manufactured media. Category 1 does not allow for any size-reduction of the soil treatment area whether it is a bed or trenches. Category 2 allows for a 10% reduction in the soil treatment area. Category 3 allows for a 30% reduction in the size of the soil treatment area.

So, as you can see the design engineer has many ways to solve the site issues that are presented. The engineer carefully considers the soil type, the site topography, and material costs within the available option in the code. In the front range, the size of the soil treatment area may be less of an issue as compared to a site in the foothills. The site in the foothills may be on a steep slope or the lot may be small and the area to install the system is marginal.

The design engineer specifies the most cost-effective system to be installed. A pressure-dosed chamber system may be the most economical to install and theoretically it will not fail prematurely because the system will have an aerobic environment in the soil. While this may be true in the short term, the useful system life is finite. It is not a matter of if an anaerobic TL2 system will fail, but a matter of when it will fail.

Every anaerobic is designed to fail regardless of how well it is designed. You may ask the question: “If design engineers and state regulators know that anaerobic systems will always fail, why do they allow them to be installed?” The short answer may be if the system last 15 – 20 years that is sufficient as nothing lasts forever. Or they just do not understand the biological science that occurs in the soil treatment area.

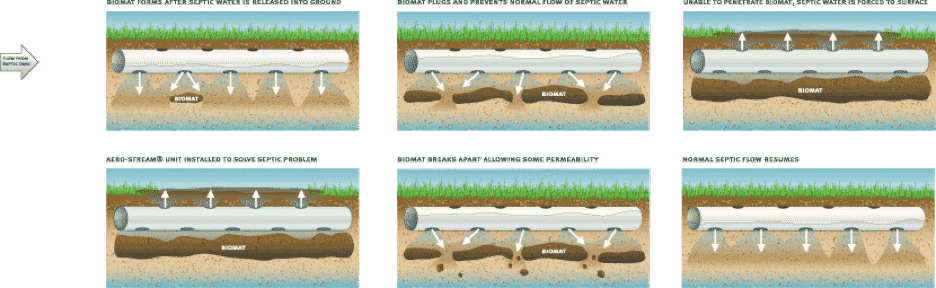

Theoretically, if the effluent is dosed to the soil treatment area of adequate size the system will operate in an aerobic environment. Unfortunately, this does not happen in the long term. As the system ages, a layer of anaerobic bacteria (bio-mat) grows into the native soil from the bottom of the trench or bed. Again, theoretically, the natural aerobic soil bacteria digest the bio-mat from below keeping its permeability in check. We know from our 22 years of experience that this theory does not hold up over time.

Eventually, the bio-mat becomes impermeable, and the system goes into failure. Some engineers and regulators will tout how well a sand filter performs at reducing CBOD5 and TSS. I agree 100% that sand filters do a wonderful job at reducing effluent strength. However, I will also tell you that the sand filter will eventually fail. When the sand filter fails it can be a costly repair. If the site has enough room for a replacement system, you may be in luck. If the site is tight the state code may allow a new sand filter to be installed at the same location, but the infiltrative surface must be lowered a foot. Either way, there will be an expensive excavation in your yard.

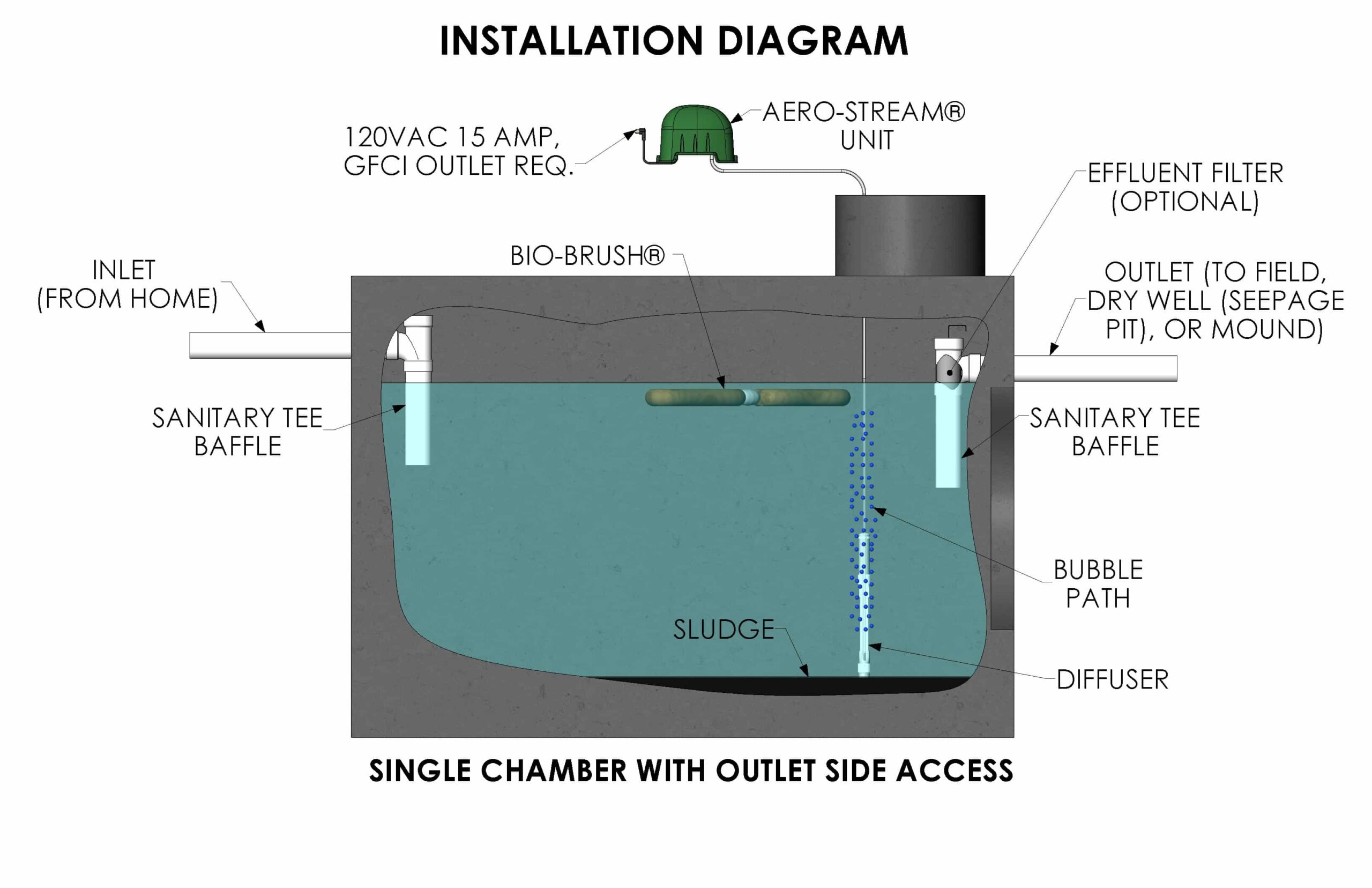

The alternative to an expensive system replacement is to install a robust mechanical aerobic treatment unit (ATU) capable of TL2 treatment level. There are several reasons why an ATU will keep your system functioning for a significantly longer time. To begin, with a TL2 ATU installed, 85% – 90% of the reduction of CBOD5 is done in the treatment tank, not in the soil treatment area. Second, these ATUs are tested to the ANSI/NSF 40 standard. They are fed influent with a 30-day average influent strength between 100mg/l – 300 mg/l BOD and TSS between 100 mg/l – 350 mg/l for 26 weeks at full rated capacity in gallons per day (GPD).

The alternative to an expensive system replacement is to install a robust mechanical aerobic treatment unit (ATU) capable of TL2 treatment level. There are several reasons why an ATU will keep your system functioning for a significantly longer time. To begin, with a TL2 ATU installed, 85% – 90% of the reduction of CBOD5 is done in the treatment tank, not in the soil treatment area. Second, these ATUs are tested to the ANSI/NSF 40 standard. They are fed influent with a 30-day average influent strength between 100mg/l – 300 mg/l BOD and TSS between 100 mg/l – 350 mg/l for 26 weeks at full rated capacity in gallons per day (GPD).

During the testing, the systems can be exposed to spikes in influent strength reach 600 mg/l BOD5. Additionally, the systems are stress-tested to ensure they can handle spikes and valleys in loading. Finally, because these systems do most of the wastewater cleansing in the tank rather than the field the soil treatment area will not develop a clogging bio-mat which is the cause of at least 95% of system failure. I recommend a TL2 system vs a TL3 system because of operating and maintenance costs. To obtain the TL3 treatment level the electro-mechanical systems are much more complex. This complexity drives up maintenance requirements and drives down reliability.

Now that you understand the advantages of aerobic treatment let’s do some simple math. Let’s say you have a new 3-bedroom anaerobic system designed and installed. The cost of the system is $20,000 and the expected useful life is 20 years. Assuming you have the $20,000 cash to pay for the system, so we won’t calculate interest. If you have a mortgage on the system, it will be more per year. The 100-year historical inflation rate is 3.26%. Therefore in 20 years, the cost to replace the $20,000 system will be about $36,000. The cost to own the system will be $1,800 per year to replace it. You will need to pump the tank out every 3 – 5 years at $300 per pumping.

So pumping 5X * $300 / 20 years is $75 per year. If you have a big flat yard and the system replacement will have minimal impact on your landscaping, repairs are $2,000. If you have a well-landscaped yard or a tight site, you may need to add another $10,000 to the project for repairs to the landscaping. The cost of ownership on the low end is about $1,875 per year. The cost of ownership on the upper end may be $2,375 per year.

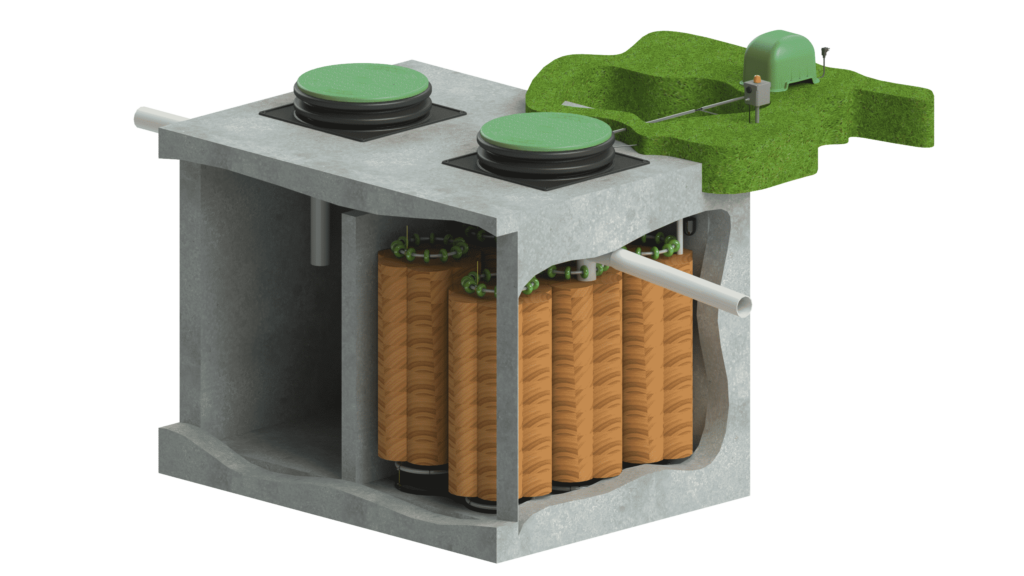

As an option, you elect to install the same system as noted above except you install an Aero-Stream Eco-Nest AS450-2 ATU in the 2nd chamber of the septic tank. The ATU installed has an additional cost of $3,600. Based on our experience to date, converting a failing passive anaerobic system to aerobic will increase the life expectancy by 2.3 times. To be conservative let’s say the life expectancy doubles. So, the aerobic system will have a useful life of 40 years at a total cost of $23,600 amortized cost of $590 per year for the first 20 years. The compressor will need servicing every 3 – 5 years at a cost of $275 per servicing or $69 per year to get you to the 20-year failure of the anaerobic system. The electrical operating cost of the compressor is about $7 per month x 12 = $84 annually. You may also need a service contract required by the state or county at a cost of $200 per year. The cost of ownership on the high end is $943 per year. The cost of ownership on the low end is $866 per year.

One may argue that “I’ll never stay in my house 20 years, so I don’t care”. As you may know, most banks or mortgage lenders, and many states require a septic inspection at the time of sale. Anaerobic systems do not fail catastrophically, they slowly fail over time. At ten years into the service life, there may be some ponding within the trenches or bed. This will be reported on the inspection report and will throw up a red flag for the buyer. This is one of the biggest fears of sellers and Realtors. And yes, we receive calls every week from frantic sellers and Realtors asking for our help.

So, if you are installing a new system you should consider adding an Eco-Nest ATU from Aero-Stream. If you have an existing system, make sure it continues to function as designed by installing an Aero-Stream remediation system. Call us at (877) 254-7093 for a free consultation to answer your questions and concerns.